SEN-AIR

An enhanced system for drying grain in the agricultural setting.

Ready to License or Manufacture

The engineering and patent work is complete!

SEN-AIR is ready for licensing or manufacturing today.

Watch!

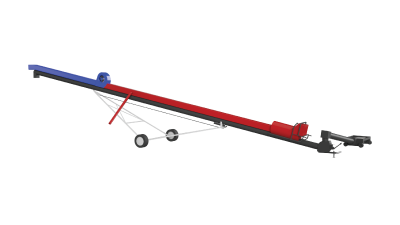

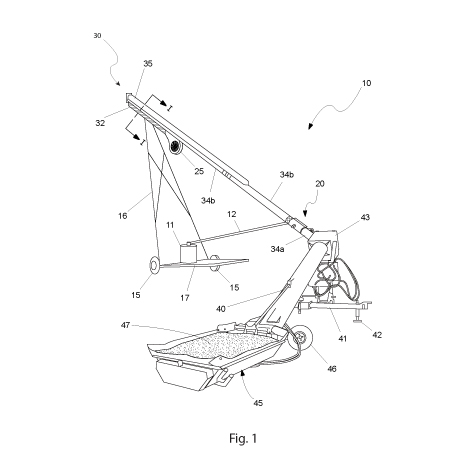

See SEN-AIR in action. This 3D animated video will provide a detailed look at the features and benefits of this invention.

Purpose

Created by Inventor Johnny F. Sen, SEN-AIR is an enhanced system for drying grain in the agricultural setting.

SEN-AIR uses an enhanced heating exchange venting system to create warm and cool air for cooling grains after the drying stage so there’s no heating or spoilage.

The system is also very cost-effective.

For great ease and convenience, no outside energy is needed. All energy is supplied from the machine that moves the auger around.

The Problem

If grains become moist from harvest, transit, or storage, it can damage the grade of grain and possibly even destroy it.

The Solution

… But now, there’s SEN-AIR!

Contact Us

Contact us NOW to learn about manufacturing, retail, wholesale, distribution, or licensing opportunities for SEN-AIR.

Heating Exchange Venting System Creates Warm and Cool Air

Cools Grains After the Drying Stage So There Is No Heating or Spoilage

Very Cost-Effective

No Outside Energy Needed

All Energy Is Supplied from the Machine That Moves the Auger Around

Story Behind the Invention

Inventor Johnny F. Sen of Canada has developed an enhanced system that simplifies drying grain in the agricultural setting.

The current process of harvesting, transporting, and drying grain is incredibly time consuming and costly. Aerate bins can take 2 to 3 weeks to dry grain but depending on humidity levels, they can take even longer. To streamline this process, Inventor Sen was inspired to create SEN-AIR!

But how does it work? The invention uses an enhanced heating exchange venting system to create warm and cool air for cooling grains after the drying stage so there is no heating or spoilage. The system is also very cost-effective. It is only 1/3 of the usual cost to set up! For great ease and convenience, no outside energy is needed. All energy is supplied from the machine that moves the auger around. This creates less of an environmental impact. Also, instead of handling the grain 4 to 8 times, you now have control of it by the push of a button.